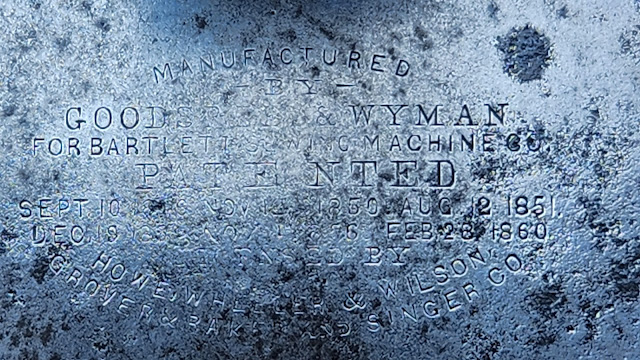

Today I would like to share a pretty special sewing machine. It's an 1867 Bartlett chain stitch sewing machine made by the Goodspeed & Wyman Sewing Machine Co. This machine is the second oldest machine in my collection.

There seems to be two different versions of this machine as seen in the patents below. As you can see, my machine is the version on the left that has the smaller hand wheel. I've also seen an example of the version on the right and the serial number was only about 100 later than my machine. The version on the right has a larger hand wheel and fewer mechanical parts under the cloth plate.

I saw this machine list for sale on FB Marketplace in early June in Seneca PA. After doing a little research and realizing what it was I quickly made arrangements to go see the machine. Not knowing much about these machines I wasn't sure if it had all of it's parts or not.....but, you don't run across these machines every day so I figured I would take a chance. I made a deal on the machine and headed back home. When I got home and showed my wife what I had bought and I think she thought I was crazy. The machine was pretty rusty and didn't move much at all.

Below are the pictures from the FB ad....

After messaging the seller they sent me the following pictures...

As you can see from the pictures this machine was not in good condition. I wrestled with not doing anything to the machine but I wanted to make it semi-functional so I decided to derust the machine. I also conducted a delicate cleaning of the machine. In some spots, the gold leaf decoration was very delicate and basically was flaking off.

The machine was missing two knobs, a couple of brass springs, a needle bar screw, and a needle set screw. I ordered some brass music wire to make the springs. For the knobs, I modified knurled brass knobs that I bought from Lowes. They're not exact to the original but they do the job! For the missing screws, first I had to figure out what size and thread they were. Luckily I did have one needle bar screw and I was able to determine it's size/thread. Of course, they were an odd thread size that isn't made anymore. They were #4-36TPI. After doing some searching I was able to find some screws that would work....but I had to but a box of 150 of them! That's ok as.they worked perfectly. The needle set screw had to be cut down to size to shorten the screw. Let me tell you, it's not easy to cut such a small screw!!!

In addition to missing parts, it appears that this machine was dropped at some point because there were three things that were bent and needed to be straightened; 1. the spool pin, 2. the hand crank handle, 3. the bolt that secures the hand wheel and the main gear on to the machine. It's always risky trying to bend things back straight but these three items cooperated and didn't give me too much trouble.

Below are the pictures of the final results. I'm pretty happy with the way it turned out and pleased that I was able to bring this sewing machine back to life.

I love the way this machine sounds!

Wow! What a great clean up job you did on that machine. It's lovely now. Congrats!

ReplyDeleteThank you Cheryl!

Delete